Solar Work of Robert Foote Shannon

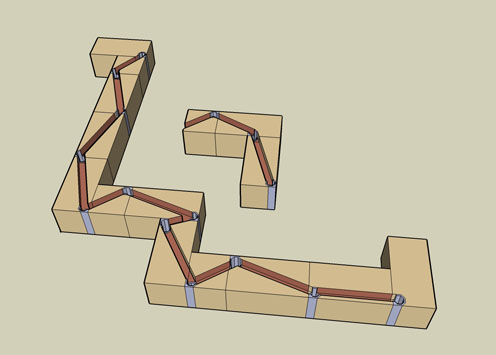

Cast Block Wall System (CASTECO) Page 2

New Casting Materials and Block Configurations Winter '07/'08

Material

A composite of 5 parts cellulose fibre, 5 parts perlite, and 1 part portland cement by volume ( this is yet vague) with water to saturate to a paste adequate to mold the material into a form ( place versus pour) produced a very porous solid of lightweight, but quite rigid. After room temperature curing, the sample was re-immersed in water until all the pores were saturated with no dissolution occurring. The sample dried out and maintained its former characteristics. Extrapolating to a solid 8"x8"x16" block, the weight would be 20 lbs. It appears to be strong in compression, and may be able to bond to some degree to rebars, or fasteners of varied materials. The rigidity and non-crumbliness of the edges is a valuable attribute for its resistance to damage in transportation and assembly. Unlike AAC no energy is needed for curing. The pumicecrete in common use in New Mexico, by contrast, is extremely crumbly, and as suggested 10 years ago to one of the manufacturers would benefit from the addition of some type of fibres ( as used in GRFC panels). We intend to have the material compression tested and tested for an accurate R value which we estimate to be slightly under R4/inch. Also precise proportions of the composite will be determined.

Configurations

The insulative core is to be made of a matrix of perlite or pumice, bonded together and to the outer and inner wall substrates with a bonding agent (acrylic?) and fibres as reinforcing. This matrix should be capable of transferring some shear, compressive, and tensile loads between and along the edges (inn all directions.) Void trenches cast in this matrix can accommodate reinforced concrete superstructure and small wires and pipes for mechanical purposes. This material, along with the substrates should be cutable with a diamond blade saw.

The outer and inner wall substrates should be made of a waterproof and fire-resistant composite board, currently available on the market. Its thickness could vary in response to desires for thermal mass, strength, weight, etc. The board should be of a high recycled content, and provide a good surface for bonding a stucco finish or allow attachments such as brick or veneer ties by screws without splitting.

Other Manufacturing Methods

Using a cnc printer to deposit layers of various material strengths and insulative values can solve the problems of curing, transportation strength, bearing strength, and bonding to grout around rebars. In fact completely customized blocks are possible on an order to order basis. From our various tests it is evident that the same ingredients in different proportions will accomplish this and bond to each other as the deposition occurs in their non-cured state. We would like to experiment with such a technique and are looking into a collaboration with an engineering or architectural school which have machines of this nature. We would appreciate any help we could receive in this pursuit.

The Market Place

It would appear that aerated autoclaved concrete will be the replacement for traditional concrete masonry units, that is if the European and Australian recent models are to spread. Lack of availability, lack of economical customized orders, and further, lack of trained applicators, make this an iffy proposition in the US at the moment. It is far superior to its competitor, but also still not putting the right material in the right places to maximize materials sustainability.

It would be a boon to architects and their clients is a one material wall ( plus coatings) were to make a suitable wall section for cold climates, especially for a zero-carbon solution. AAC will not do this in a reasonable thickness, even with its mass factor, under prolonged cloudy conditions, and on non-solar immersed walls. It is a problem comparable to Trombe wall solar systems. You just cannot escape the entropy without a hefty R value.

Page 1 | Page 2